The screwless spinner idea I got From Rick Gray who got it from somewhere else. The idea is to take a Vans spinner and mount it so there are no screws showing. It makes bug cleaning easier, waxing easier, and most importantly, your RV buddies will stare in amazement at your spinner on the ramp and shout "Hey, Where are the damn screws?"

You start the process by following normal mounting procedures with centering the spinner and cutting the holes for your prop blades. Once you have it centered and turning true, you may begin this process.

1. Remove the prop and remove the rear bulkhead from the prop hub

2. You cleco the spinner in a few places, say 8 places, onto the rear bulkhead to hold the position. Dont worry about these little holes, you have plenty of filling to do on the spinner later and you will fill these in when you do.

3. You get one show at this so make sure the spinner is turning true before you start all this. Now your ready for the flanges. What your doing is making an L flange out of fiberglass. One side on the spinner, the other on the fwd face of the rear bulkhead.

4. Apply shipping tape or other release agent to the bulkhead so your lay up does not stick to the bulkhead. I used car wax as its clean and easy to apply.

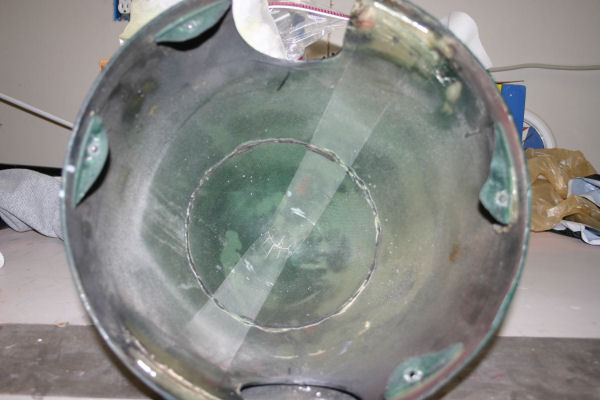

5. With the bulkhead clecoed on, reach in through the big hole where the prop hub goes and do your layup. Lay up about 4 layers of 9oz cloth by reaching in through the bulkhead and laying them up. When you remove the bulkhead, you will have a flange around the spinner. Like this picture here.

6. Put the bulkhead back on and back drill the bulkhead into the fiberglass flange you made. 8 Holes in all will do it. Remove the bulkhead and put in your nut plates. I used -3 10/32 nut plates. I also run a tap through em to make em not so tight. Mark your spinner relative to the bulkhead with a sharpie for orientation.

7. Clean up the flange and the spinner by trimming it. Mount the bulkhead to the prop again.

8. Wait, your not done. Now what you want to do is create a nice seal between the spinner and the forward bulkhead so it so it wont move around in the front. You do this by applying a release agent to the fwd bulkhead. Then get out your dreaded proseal and apply a bead to the fwd bulkhead flange where it will contact the spinner. Then mount the spinner. Let the proseal set up. And you should have a nice bead on the spinner, Here is mine.

OK NOW your done.

9. Whalla, your done. With any luck, it will look like this. "Look Ma, no screws."

This technique above was my second try. On the first try I made flanges only where the nut plates were going to go. DON'T DO THIS! They will break off. I left these pictures here below to show you what NOT to do. You need a full length flange around the spinner.

Back to Super 8