Fluting (pronounced "flute" "ing")

Fluting is the process of straightening the aluminum parts by crimping them. Some of the plane parts come pre-punched, like the ribs for example. The manufacturing process causes the ribs to be bent and you must straighten them. Here is a rib, laying flat on a piece of wood. Notice it is bent up and not laying flat.

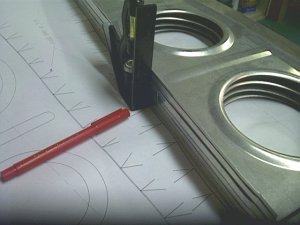

Next you lay the rib on the plans and mark each place where a bend can be made. (bends can not be made where rivets will go. So basically every inch is a rivet, and between them can get crimped/bent to straighten the rib. I mark several ribs at once.

Then you take a pair of fluting pliers like these (sorry for the blurry picture).

Then make a crimp in the metal, shortening the length, causing the whole rib to straighten. Each rib get about 25 of these crimps to straighten it.

With each crimp, you sight down the length to see how much more crimping is required. (here is Arlon, my soon to be step dad in-law, helping me through the fluting during his Christmas visit.

Then crimp some more!! Until it is perfectly straight. Notice the ribs all over the place. There are many of them to do. Plan on about 8 hours of fluting to complete the process. Thanks Arlon.

last updated 11/05/02