For a definition of uttoos, see my first one.

Uttoo number 2 of ??

This uttoo happened for 2 reasons. The first is normal, dumb human error. The second reason is a new one and is probably going to crop up again from here on out. I am calling this type of error "the flip-flop syndrome". Here is how it works.

The plans are very clear, except they only show you one half of a view and force your mind to do mental flip-flops to figure out the other side. In this case, the plans show you the left wing tank drawing. You must "vision" the other tank as the opposite of the left. Only not everything is opposite. Only some things.

Think of it like this.. When you are driving down the road, left is left and right is right, up is up and down is down. But when someone is coming at you while driving, left is right, and right is left.. BUT, up is still up and down is still down. So only some things are backwards. Get it? Well when building 2 things simultaneously, a left tank and a right tank, keeping your lefts and rights straight is not easy, even when concentrating HEAVILY. You do so many flip-flops, that your doing flip-flops on your flip-flops, and not really flip-flopping at all if your not careful. Clear as mud?? Good, lets continue..

I started with a very nicely formed wing rib seen below:

Then, while my mind was heavily engaged in the mental aerobics of flip-flopping, proceeded to cut out 2 holes.... and.... well I was only supposed to do it in one rib, not all 8 ribs. So I ended up with a bunch of ribs with holes in them. Normally, you would just call the manufacturer and say "gimmie 8 of them ribs I just screwed up" and they would be in with in a week. But Nooooo.., I had to attempt a fix with the very well thought out idea of welding the cut outs back in place. (see the "nothing went to the shop" section on why I did this.) Now this, like all the parts on this plane, is aluminum.... and like everything else requires a "special" welder. A mig welder to be exact. I called around some welding shops and it was going to cost me $200 to have them welded. And for twice that, I could own my own welder. So off to ye old trusty local Home Depot to get a Lincoln mig (wire fed, and argon gas assisted) welder.

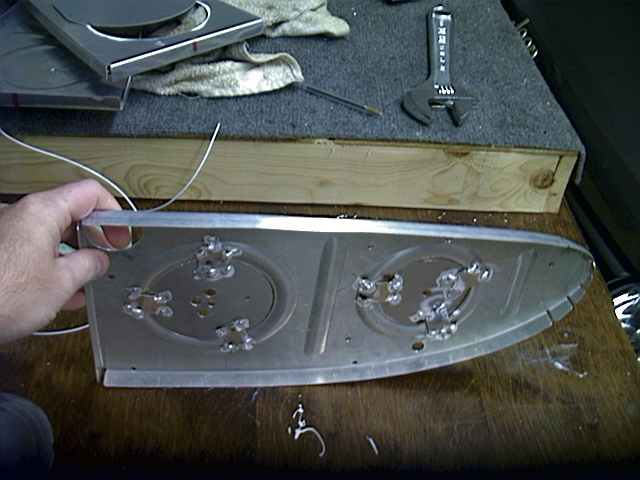

For various reasons only a "real" welder would know, it came out like $#@$%@. Probably having to do with some material thickness issue, wire feed speed, or some other reason (like I have no mig welding skills for example). It came out like this below.

Now structurally its fine, but due to fuel flow rates in the tank, and various other mundane aeronautical issues, this turns out to be neither acceptable nor respectable. So I had to toss em and do what I should have done from the beginning and just ordered new one's. Another lesson learned I hope.

Last Updated Tuesday, November 05, 2002